Challenges in Pharmaceutical Supply Chains

The pharmaceutical industry faces dual pressures from regulatory policies and market demands. With the rise of internet-based healthcare and new retail models, distribution channels have multiplied while orders become increasingly fragmented. This complexity demands cost-controlled, agile warehouse solutions.

Intelligent Warehouse Transformation

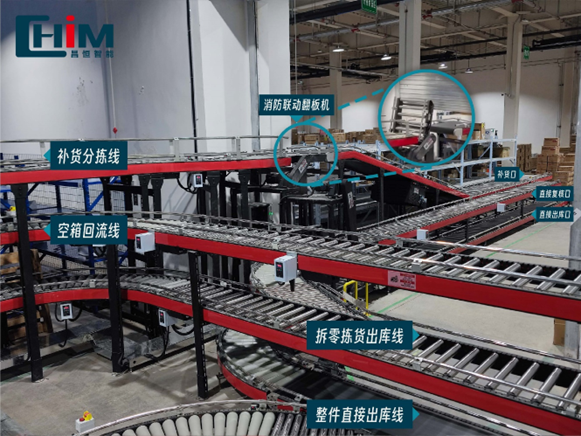

Addressing challenges like complex SKU batches and decentralized deliveries, Changheng Smart designed an integrated B2B2C warehouse system featuring:

- Five functional zones: Bulk storage, split-case picking, recheck & packing, dispatch

- Space optimization: 50%+ storage density increase through multi-level workflows

- Parallel processing: Simultaneous operations across zones with flexible scalability

Bulk Order Processing

Three parallel lines in bulk storage area:

- Direct dispatch line: Ships full cases

- Recheck line: Transfers cases to inspection stations

- Replenishment line: Restocks split-case area (2,000 cases/hour capacity)

Key features:

- Full batch tracking compliant with pharmaceutical regulations

- Fire-rated flap gates isolate zones during emergencies

Split-Case Order Fulfillment

Three-tier conveyor system enables:

- Top layer: Automated replenishment from bulk storage

- Middle/lower layers: Case transfer between picking and packing

- Modular pusher diverters: Route cases to 300+ packing stations

Technology integration:

- Light-directed picking ensures 99.9% accuracy

- WMS-driven data tracking from storage to dispatch

System-Wide Synergy

By harmonizing human expertise with automated technologies, this solution:

- Optimizes staff workflows through ergonomic design

- Maintains strict temperature/humidity controls

- Enables multi-channel fulfillment without batch processing bottlenecks

-英文官网.png)